Energy

Focused on Productivity

Carbon fiber demand is growing in the wind energy market to manufacture wind turbines that will generate electricity at costs that meet or beat traditional generation technologies such as coal, natural gas and hydropower. However, as wind blades become longer, it is essential to reduce weight while maintaining strength and stiffness to maximize energy production efficiency.

As the wind energy sector strives to produce turbines that generate the lowest cost of energy, carbon fiber composites offer greater stiffness, lower weight and optimized cost. With its commitment to bringing the benefits of carbon fiber to the industrial marketplace, DowAksa offers this enabling technology for new generation wind turbine blades.

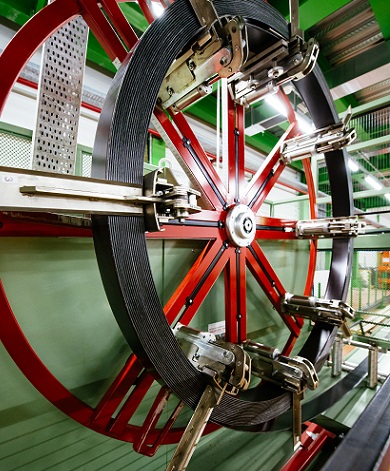

We offer carbon fiber reinforced polyurethane- resin based pultruded profiles/laminates for Spar Caps of new generation, longer Wind Turbine Blades. We produce laminates using advanced process technology that assures the strength, stiffness and lighter weight needed for more productive, reliable and efficient wind turbine operation.

DowAksa with full downstream integration model and capability is also helping Turkey raise the bar for local content creation in wind power projects as a significant amount of laminates for carbon fiber spar caps in wind turbine blades now will be domestically produced. Before DowAksa, these parts were imported from other countries.